Technology

Specialists in the separation technology

REDA separators offer a high level of performance in a wide range of processing in the food and beverage industries. REDA supplies separators and clarifiers designed on advanced disk stack design and top separation efficiency. All machines are based on the conceive of efficient and effective removal of suspended solids of various types and sizes, combined with gentle treatment to preserve the quality of the end product while ensuring energy efficiency, operational reliability and a high level of safety.

Quality knows no compromises

REDA separators are high-speed centrifuges that reach high centrifugal force at the top of their class. To achieve these speeds our separators are supplied with:

– Bowl in high steel quality

– Perfect bowl balancing

– Special mechanical drive

We employ Super-duplex quality stainless steel, which ensures top strength and very good corrosion resistance.

Sophisticated monitoring and recording systems are used for both high and low speed balancing to reduce at minimum the strength over the mechanical drive.

– Bowl in high steel quality

– Perfect bowl balancing

– Special mechanical drive

We employ Super-duplex quality stainless steel, which ensures top strength and very good corrosion resistance.

Sophisticated monitoring and recording systems are used for both high and low speed balancing to reduce at minimum the strength over the mechanical drive.

bowl under balancing in security room

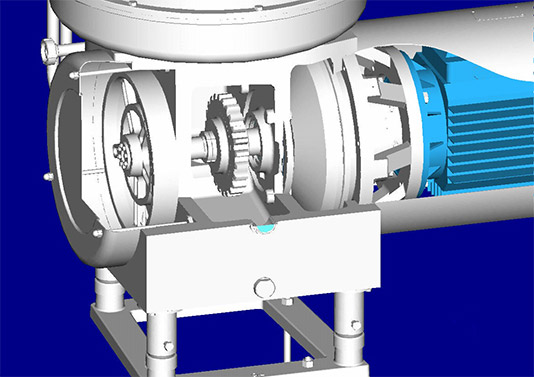

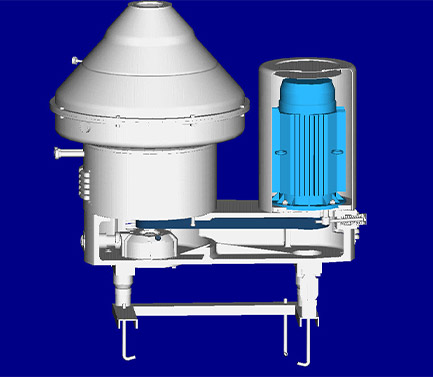

Depending on the nominal capacity, the mechanical drive can be of gear type of belt drive transmission.

Gear type transmission

Belt drive transmission

All models are equipped with the motor speed control through VFD inverter as standard:

– machines come with normal motors (no heavy-duty motors are necessary)

– no motor overheating because VFD endures motor overloads during the starting and discharges

– lower stress of the transmission system

– silent operation

– optimization of the electrical absorptions (i.e. less power consumption)

– lower wear of bearings and gears that last longer

– no maintenance necessary

Example of VFD inverters mounted on REDA separators